OUR NEXT-GEN SYSTEMS

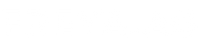

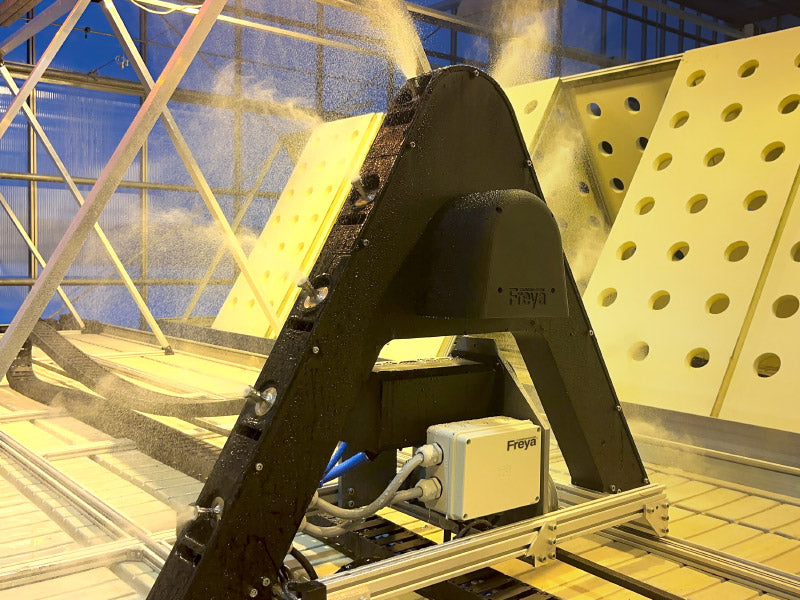

GREENHOUSE AEROFRAMES

AEROFRAMES offer double active cultivation area for growers in the leafy greens industry. Utilizing mobile aeroponic irrigators, AEROFRAMES offer the highest return on investment - while requiring the least labor. Pilot testing available.

INDOOR FARM AEROPONICS

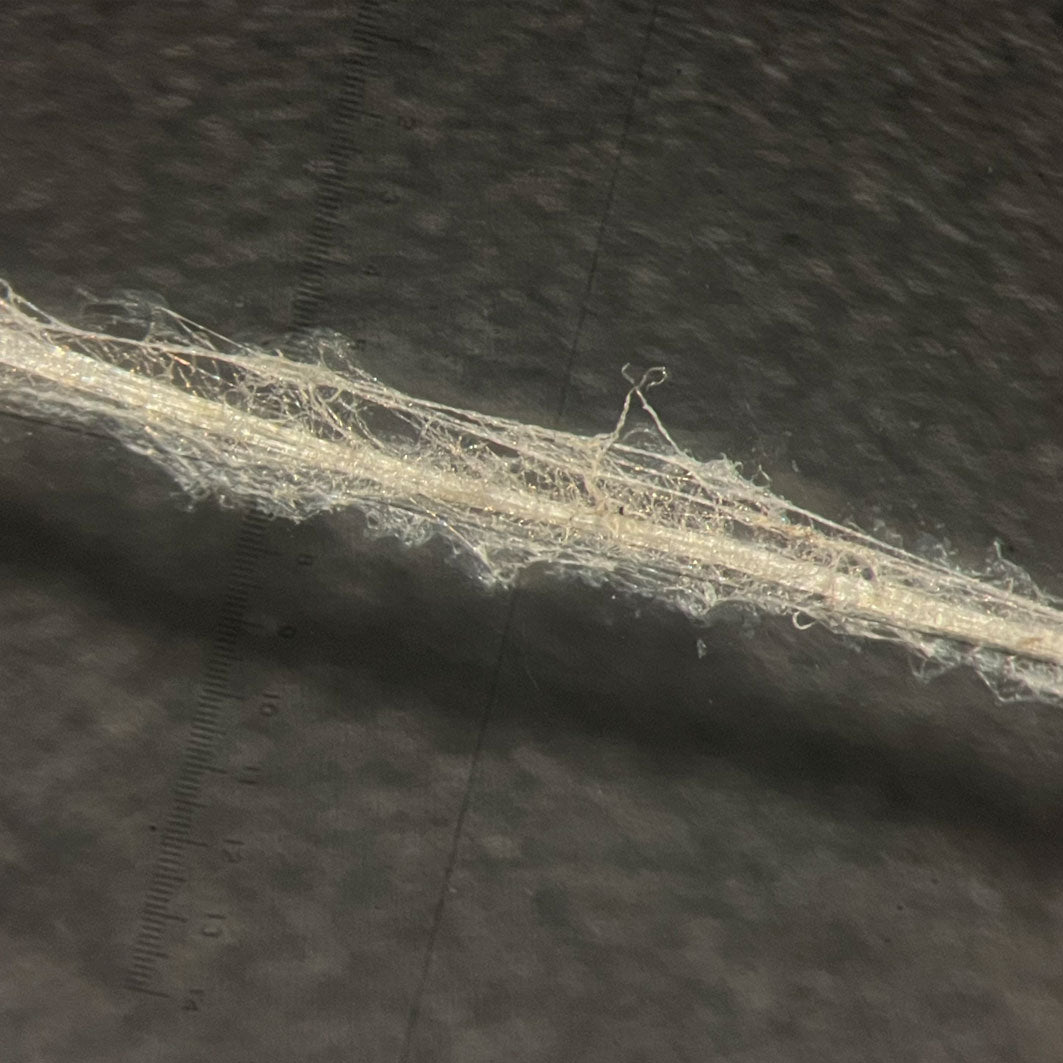

Our uncloggable aeroponic e-nozzle systems require no pressure-pumping to produce aeroponic mist. Designed to retrofit existing installations, these smart devices can work with gravity feed or a drip line. Commercial samples available.

CORE TECHNOLOGIES

FREYA has developed pressure-less aeroponic irrigators (patent-pending) that use ultrasound to efficiently break up a flow of liquid into 30-150 micron droplets. Our sprayers are uncloggable and can work with gravity feed - no high-pressure required. Because of the underlying technology, maintenance is almost non-existent.

For the first time ever, aeroponic irrigation is easy, scalable and available to you now.

LEARN ABOUT OUR TECHTIME TO RECONSIDER AEROPONICS

ARCHITECTURE GAINS

Aerosolized nutrient solution can travel in three dimensions. This means that vertical structures, such as aeroponic A-frames, towers, walls and other cultivation structures can be deployed, resulting in 2x to 10x and higher plant density per available square footage.

FASTER GROWTH

One of the standout advantages of aeroponics is its ability to boost crop metabolism. Studies have shown and our research has confirmed that aeroponic systems can deliver 10% - 30% faster crop cycles compared to traditional methods.

DISEASE PREVENTION

The elevated oxygen levels in aeroponic systems act as a natural defense mechanism against disease development. Increased oxygenation bolsters the plant's immune system, making it less susceptible to pathogens, as many harmful microorganisms thrive in low-oxygen environments.